⇩ Use mouse and click in the interface to jump down to the relevant section for any spesific element ( tabs,buttons or options ) ⇩

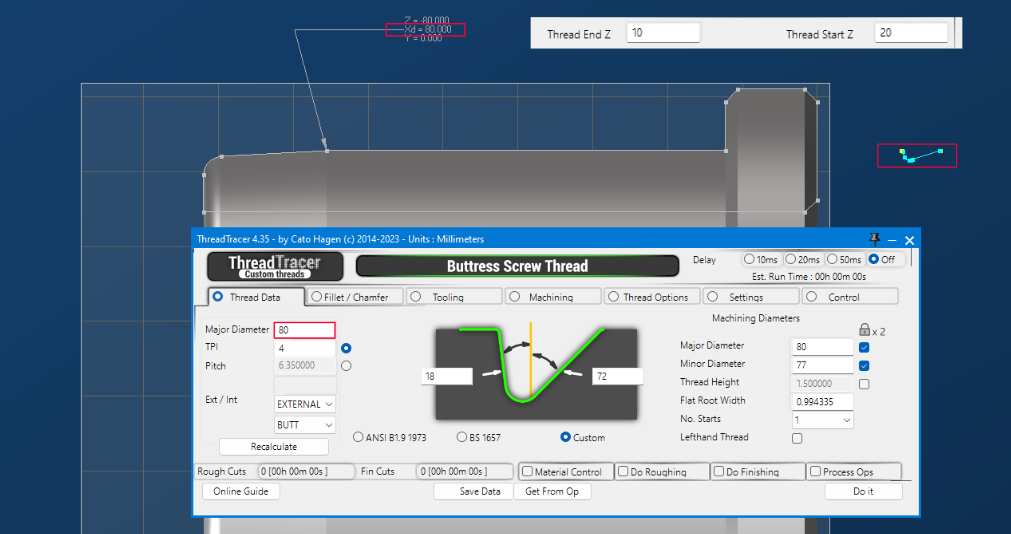

ThreadTracer uses a tabbed interface to present its parameters to you. Whatever thread is selected will have the appropriate thread data displayed on the first tab.

Switching between the different thread types are found in the Control tab. You will find descriptions for all input boxes and options in these pages.

Click the 'Online Guide' button in the plugin and it will open this online documentation in your web browser.

Round/Knuckle Thread \\ Thread Data Tab (Tab 1):

Nominal : Enter the nominal for the thread. Both DIN 405 and DIN20400 are metric thread standards, so Nominal needs to be metric for calculation.

TPI : Set the TPI for DIN 405 knuckle threads.

Pitch : Set the metric pitch for DIN20400 knuckle threads.

Tolerance Major Diameter : 6h, 7h, 6e, 7e for external DIN 405 thread.

Tolerance Pitch Diameter : 6h, 7h, 8h, 6e, 7e, 8e for external DIN 405 thread.

Tolerance Minor Diameter : 7h, 8h, 7e, 8e for external DIN 405 thread.

Tolerance Major Diameter : 6h, 7h, 6e, 7e for external DIN 405 thread.

Tolerance Pitch Diameter : 6h, 7h, 8h, 6e, 7e, 8e for external DIN 405 thread.

Tolerance Minor Diameter : 7h, 8h, 7e, 8e for external DIN 405 thread.

Tolerance Pitch Diameter : 6H, 7H for internal DIN 405 thread.

Tolerance Minor Diameter : 7H, 8H for internal DIN 405 thread.

Ext / Int : If the thread are external or internal.

Recalculate : Always click this button after the above entries have been changed, to calculate the correct new diameters, radiuses and flat root for machining.

Tolerance Pitch Diameter : 6H, 7H for internal DIN 405 thread.

Tolerance Minor Diameter : 7H, 8H for internal DIN 405 thread.

Ext / Int : If the thread are external or internal.

Recalculate : Always click this button after the above entries have been changed, to calculate the correct new diameters, radiuses and flat root for machining.

When switching between External and Internal thread, you might get red alert boxes around the machining diameters, press the recalculate button again to correct the mean machining diameters.

Calculated after clicking Recalculate button

Major Diameter, these are the max and min values allowed for Major Diameter, from current entered Nominal.

Pitch Diameter, these are the max and min values allowed for Pitch Diameter, from current entered Nominal.

Minor Diameter, these are the max and min values allowed for Minor Diameter, from current entered Nominal.

If you work in inches, the numbers in the thread table are automatically converted to inch.

Select thread standard to use when calculating.

DIN 405 - 1997 (Metric standard with TPI)

DIN 20400 - 1990 (Metric standard with metric pitch)

If you work in inches, the numbers here are automatically converted to inch.

Major Diameter : Value here is the calculated mean value between max/min from the thread table.

Minor Diameter : Value here is the calculated mean value between max/min from the thread table.

Thread Height : Value here is the calculated thread height, from the two numbers above.

No. Starts : Select number of starts, if the thread is multistart.

Lefthand Thread : Check this if its a lefthand thread.

Under the Padlock symbol are 3 checkboxes to edit and lock diameters, if the two upper boxes are checked, the thread height will always be calculated from the two locked numbers.

Locking Major Diameter and Thread Height, the Minor Diameter will be calculated with using the locked numbers.

Only 2 numbers can be locked, if all three are locked, it will by default always use Major and Minor diameter and then calculate thread height.

If you edit a diameter and enter a wrong number or deletes the entry, clicking 'Recalculate' will restore the numbers back to initial values.

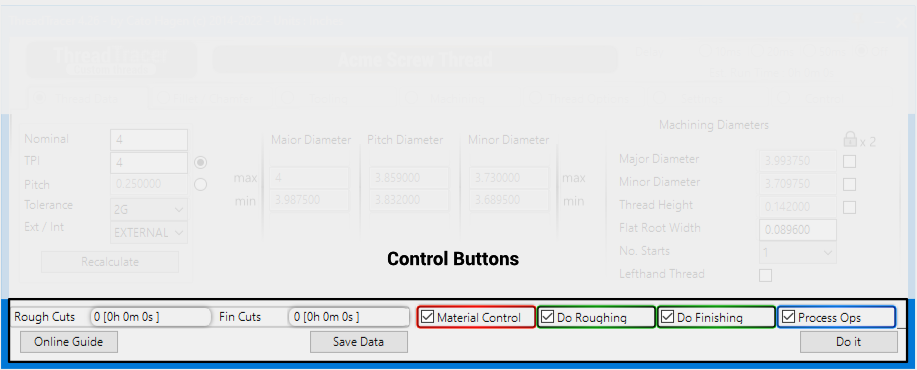

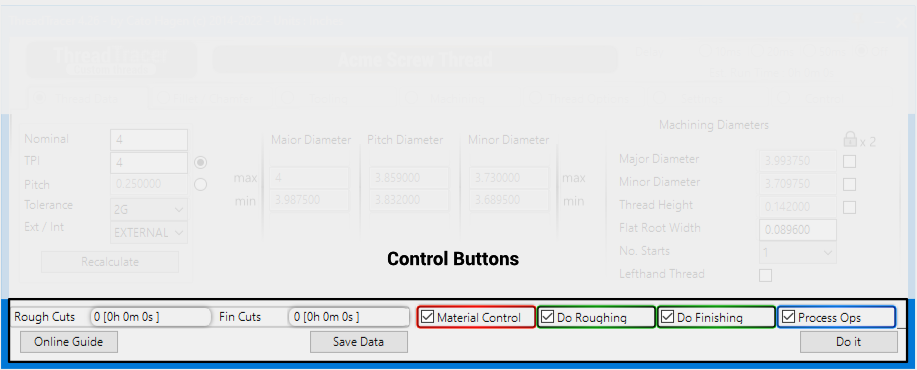

Control buttons at the bottom (Back to top)

Use the buttons at the bottom of the ThreadTracer dialog to turn on or off actions to make.

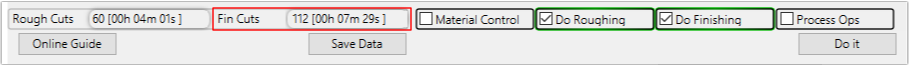

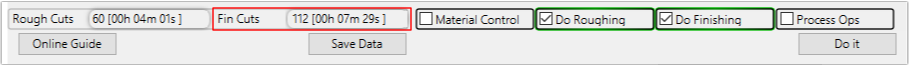

Holds information of the calculated Rough Cuts in the current programmed thread. 'amount of cuts' [ hh:mm:ss ]

Rough Cuts

60 [ 00h 04m 01s ] means roughing the current programmed thread requires 60 threading passes with an estimated machining time of 4 minutes and 1 seconds.

Holds information of the calculated Finishing Cuts in the current programmed thread. 'amount of cuts' [ hh:mm:ss ]

Fin Cuts

112 [ 00h 07m 29s ] means finish machining the current thread requires 112 threading passes with an estimated machining time of 7 minutes and 29 seconds.

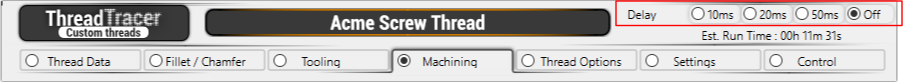

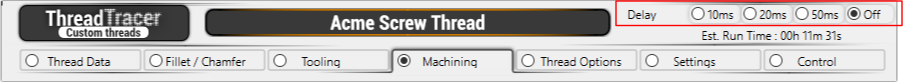

Est. Run Time (Calculated) (Back to top)

Est. Run Time shows the calculated Run Time for machining, for all Roughing and Finishing passes combined.

To improve the time estimate, you can set your machine tool Rapid Feedrate in the Settings tab. Your machines rapid feedrate can be found in the parameters of the machine.

As there are as many rapid moves as feed moves in machining a thread, setting the correct rapid feedrate will allow for a more precise time estimate.

If you work in metric, set the Rapid Feed in millimeters/minute. If you work in inch, set the Rapid Feed in inches/minute.

Default values in ThreadTracer are 12000 millimeters/minute for GibbsCAM in metric and 500 inches/minute for GibbsCAM set to inches.

Material Control ( Checkmark On/Off ) (Back to top)

Material Control : This will enable material control, and keep all threading cuts within the set limits. By default the limits are always set to Major and Minor diameter.

You can change upper and lower machining limits for Material Control in the Machining Tab.

Do Roughing ( Checkmark On/Off ) (Back to top)

Do Roughing : This will enable roughing of the thread. When enabled it will run the roughing of the selected thread with the set tool parameters when pressing the 'Do It' button.

Do Finishing ( Checkmark On/Off ) (Back to top)

Do Finishing : This will enable finishing of the thread. When enabled it will run the finishing of the selected thread with the set parameters when pressing the 'Do It' button.

Process Ops ( Checkmark On/Off ) (Back to top)

Process Ops : This will enable the creation of GibbsCAM threading operations for all the calculated thread coordinates when pressing the 'Do It' button.

Everything in ThreadTracer is controlled by the

'Do It' button.

You can turn on/off options, generate visual geometry, change cut depths, change tool sizes and everything will be recalculated and updated when you press 'Do It'.

As long as the 'Process Ops' or 'NC Postprocessor' are disabled, no GibbsCAM operations or g-code will be generated.

Set up the all the roughing and finishing of the thread and only enable 'Process Ops' when everything seems correct. With 'Process Ops' enabled it will generate GibbsCAM threading operations.

'Do Roughing' and 'Do Finishing' can be set individually. If only 'Do Finishing' is enabled and 'Process Ops', it will only create GibbsCAM threading operations for the finishing passes.

Click 'Do It' button to start running the options that's selected.

As ThreadTracer is an external plugin, there is no 'ReDo' button. If you need to change anything you must delete the threading operations in GibbsCAM and create new ones in ThreadTracer.

If you delete the threading tool instead, all the operations in GibbsCAM that used that tool will be removed, this is often faster than selecting multiple operations with scrolling for deletion.

ThreadTracer will always create a new tool based on tools settings from the Tooling tab (Tab 3) if no previous tool exists.

If you are using NC Tracer to generate g-code for machining, Process Ops should be disabled(off) and instead enable 'NC PostProcessor' in Tab 7.

Click 'Save Data' to store the current thread setup into the GibbsCAM program

It will create a new data entry if its a new thread, after the thread setup is stored the button will change to 'Update Data'.

This way you can store and update the same thread entry, and not create a completely new thread entry every time the 'Save Data' is clicked.

If you need to create a new data entry in the GibbsCAM part, you must close ThreadTracer and restart it, and it will now start with a new data entry.

With version 4.32 and higher its not necessary to use 'Save' button. All thread data from ThreadTracer are written to each operation and retrievable by using 'Get From Op' button instead.

These lines of text can also be copied and pasted into other GibbsCAM programs, to quickly recreate the thread without typing in all the parameters again.

Visual Delay Timer for in between each calculated thread pass.

The Delay Timer can be useful for delaying the visual geometry drawn in GibbsCAM. If something seems off, it can sometimes help track the error with a delay and confirm that every pass is done correctly.

Delay Timer was initially used in development of ThreadTracer, but kept it as it can be useful to slow things down if there is a suspicion of some passes not being laid out correctly.

Online Guide button will open this ThreadTracer documentation in a new web browser window.

ThreadTracer will parse information on what thread style and tab thats currently open, and redirects the web browser to the relevant page.

Clicking the 'Online Guide' while in Stub Acme and Tab 5, will open the documentation for Stub Acme and Tab 5.

This feature is available in all versions of ThreadTracer v4.35 and up.

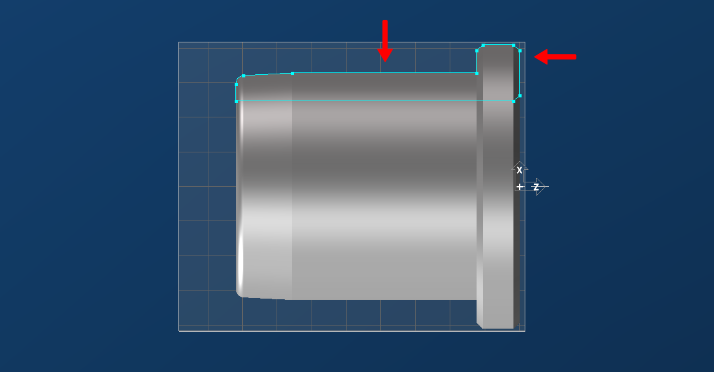

Advanced Entry & Retract allows you to select the placement of the thread on the part using point geometry instead of setting start and end using numbers.

This can be used for threads that require special placement behind a feature or around an obstacle.

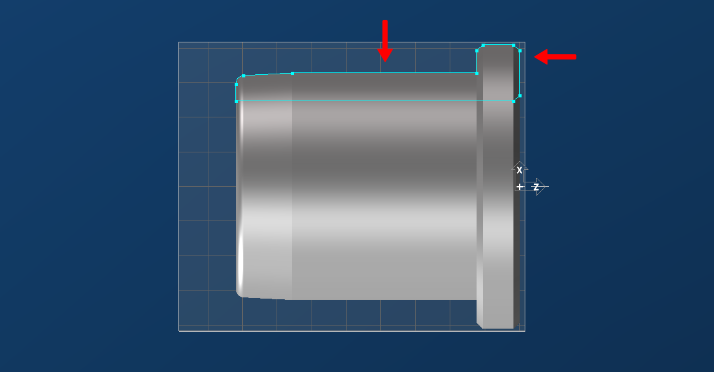

• Part for threading

Surface for threading

Obstacle

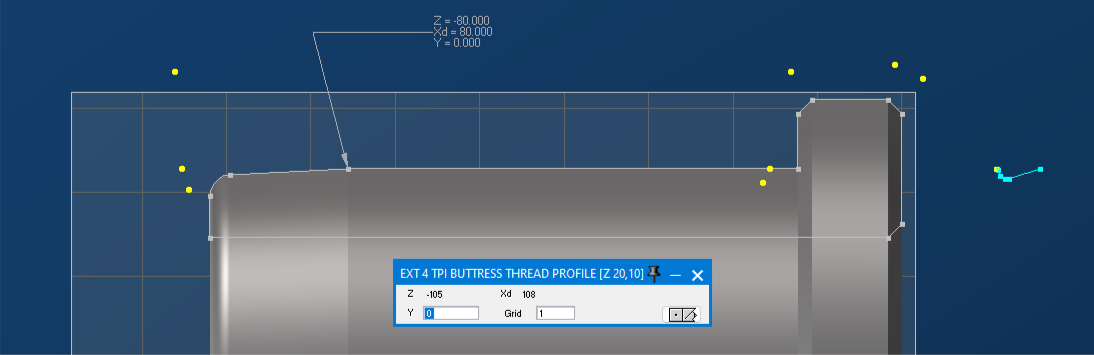

Setup the thread profile and place the thread machining positions outside the part using 'Thread Start Z' and 'Thread End Z'

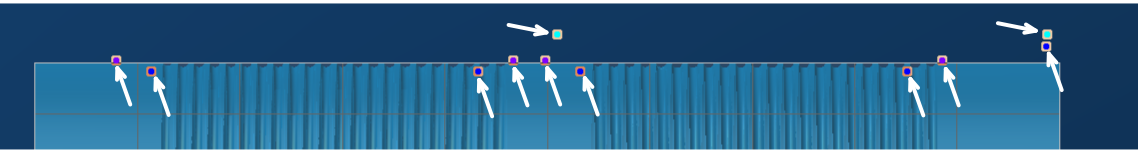

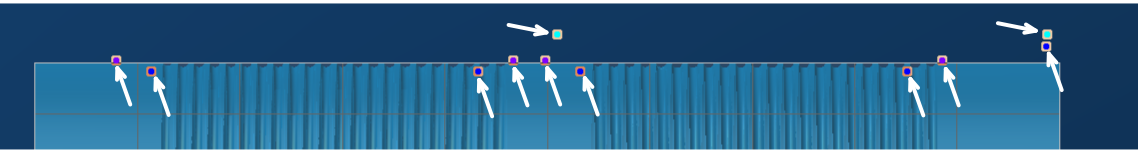

Place geometry points to be used as an extended toolpath for the threading cycle. These points can quickly be placed freehand with mouse with using 'Mouse Point' in the Geometry Palette.

The tool will always start where you placed the thread profile, so place points to guide the tool to the surface on the part.

For this example, the surface that will be threaded are behind this obstacle so we need to place points to guide the tool around.

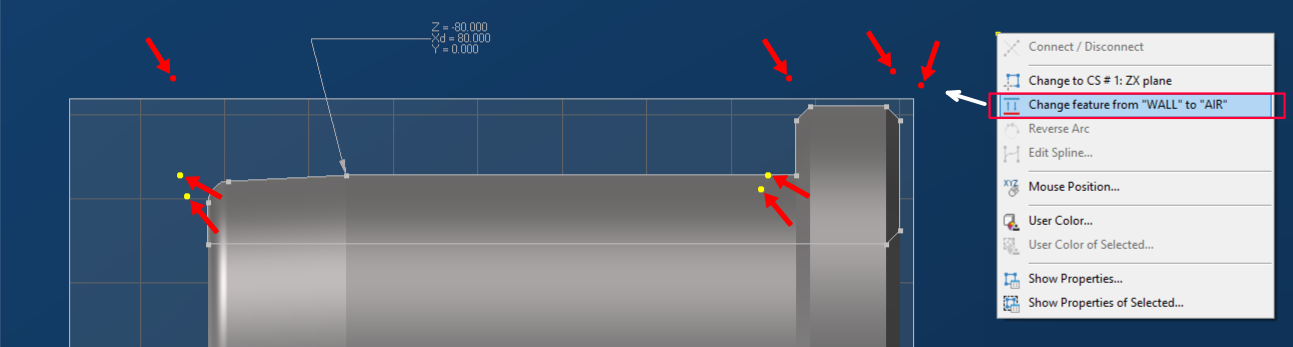

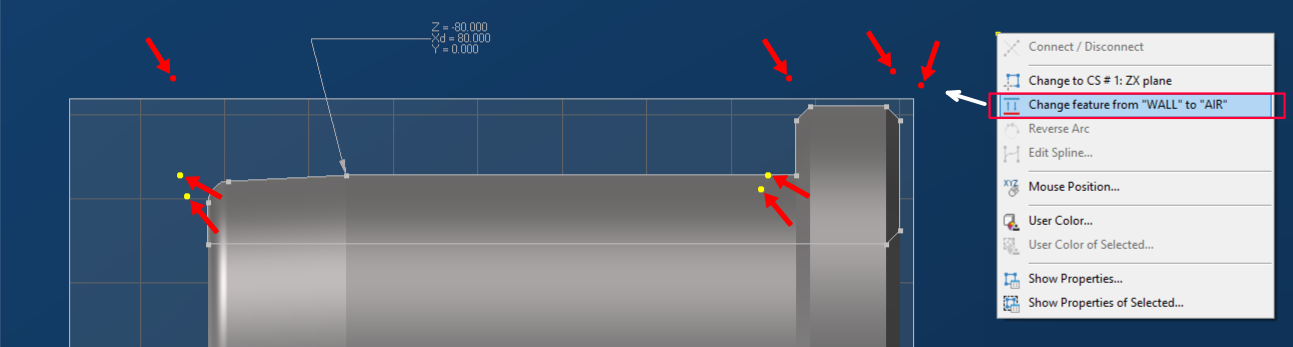

To designate a point to be an entry or retract point, select the point, right-click a point and select "Change feature from "WALL" to "AIR".

Do this to every point where the tool needs to move in air.

Entry point 1

Entry point 2

Retract point 1

Retract point 2

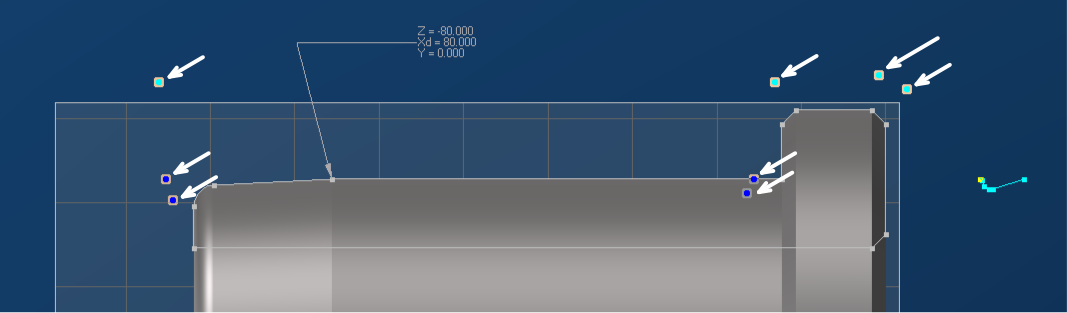

Thread point 1

Thread point 2

Thread point 3

Thread point 4

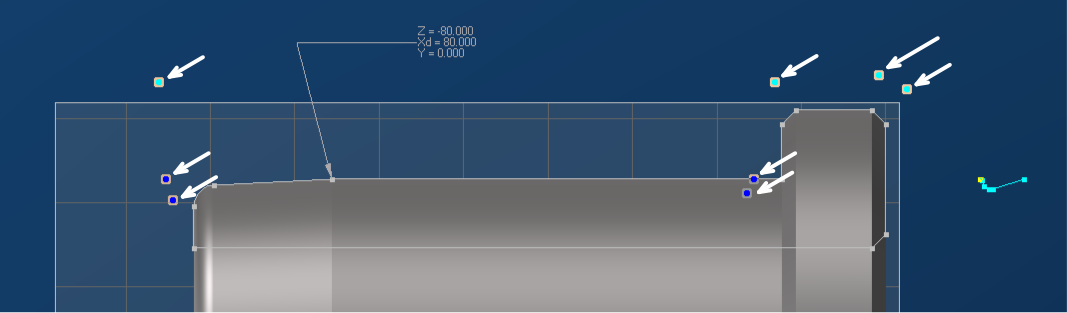

By selecting these points in a spesific order, you select the points used for entry, points used for thread surface and points used for retract and return back to start.

All points that have been set to "AIR" (red) will automatically be set and used as entry and/or retract points by ThreadTracer.

Points that are normal (yellow) will be used as thread surface.

Thread point 1 -> 2 will be equivalent to a Run-In angle, therefore you can place Thread point 1 in an angle in relation to Thread point 2.

Thread point 2 -> 3 will be equivalent to 'Thread Start Z' and 'Thread End Z'.

Thread point 3 -> 4 will be equivalent to a Run-Out angle.

Points to be used as thread surface needs to be sets of 4 points.

All red points selected after normal points (yellow) will automatically be used as retract points by ThreadTracer.

Select points by holding CTRL key while you click and select the points in the order you want the tool to move.

1.

2.

3.

4.

5.

6.

7.

8.

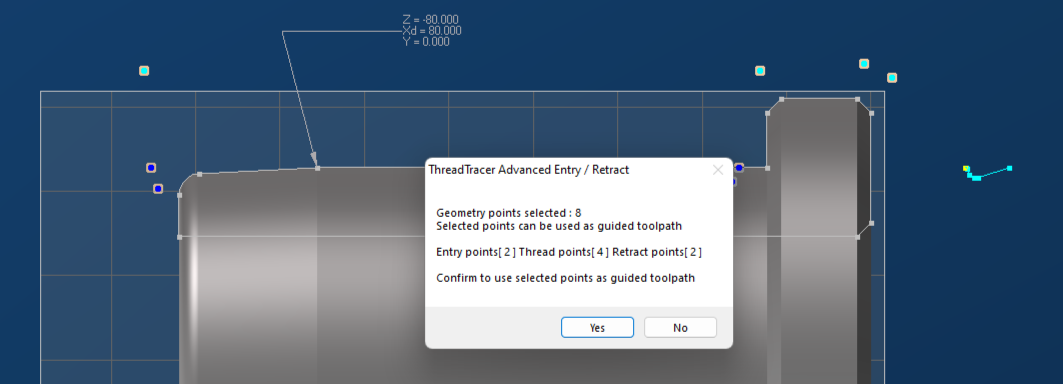

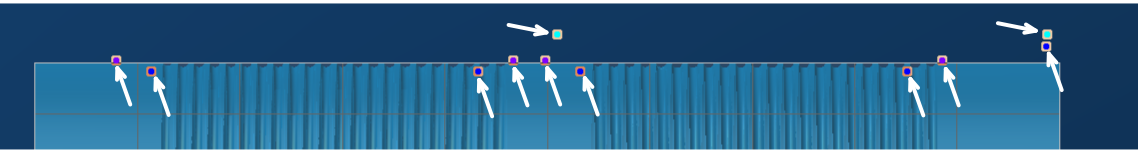

With the points selected, pressing 'Do It' in ThreadTracer will bring up a window with information about the points.

The points are automatically sorted and arranged as a new toolpath in the same order as you selected the points.

Confirm to use the points as a guided toolpath by clicking 'Yes' in the window.

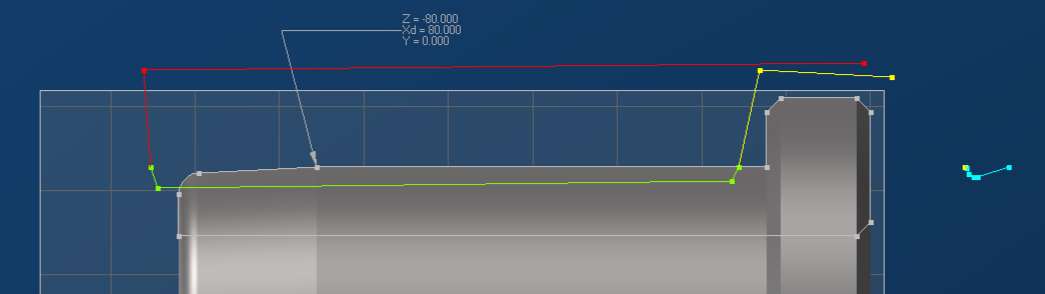

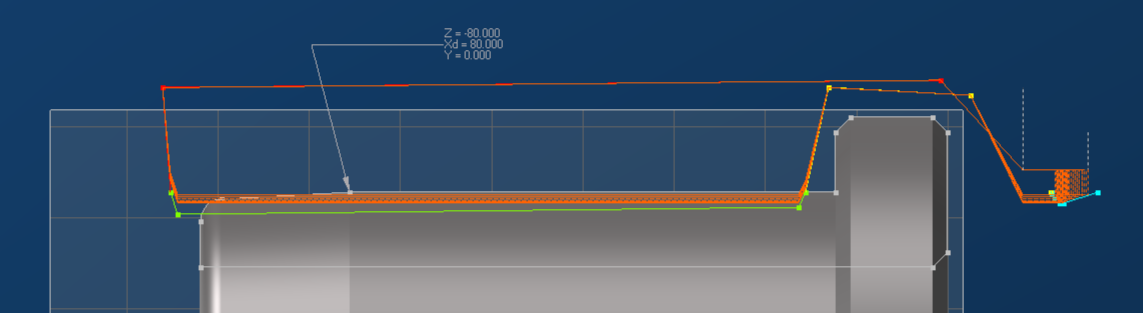

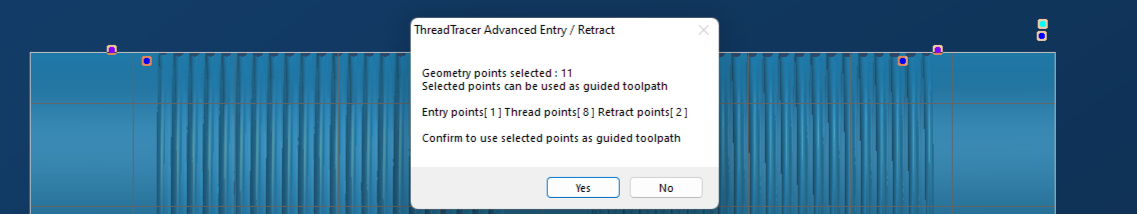

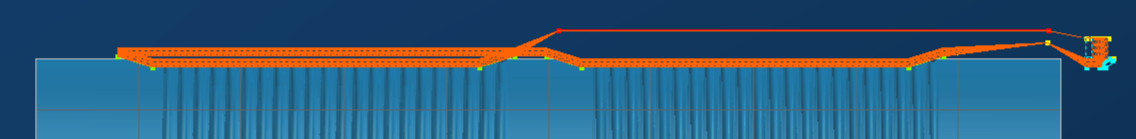

The new toolpath will be built with colored lines to visually identify the different features.

Yellow lines represent entry toolpath.

Green lines represent the toolpath for the actual thread.

Red lines represent retract moves for the tool (rapid moves).

Yellow lines will be output as part of the thread, ie tool moves with G32/G33 to keep the tool and spindle in sync.

The new point based toolpath will stay in memory until you close ThreadTracer or select new points again.

Generate roughing and finishing operations or adjust parameters for cutting and recreate operations, and it will use the point based toolpath.

Multiple Thread Surfaces / Synchronized Lefthand & Righthand threads (Back to top)

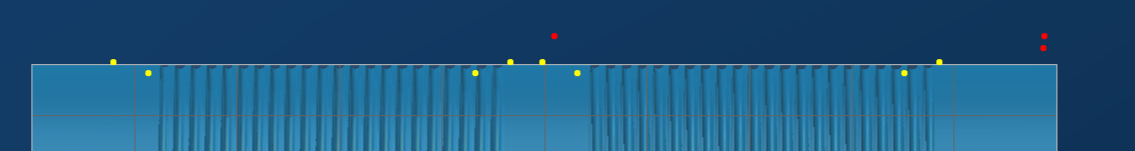

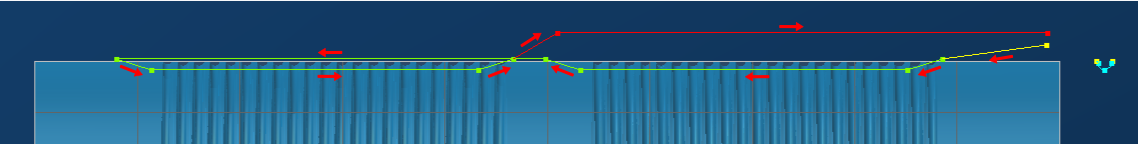

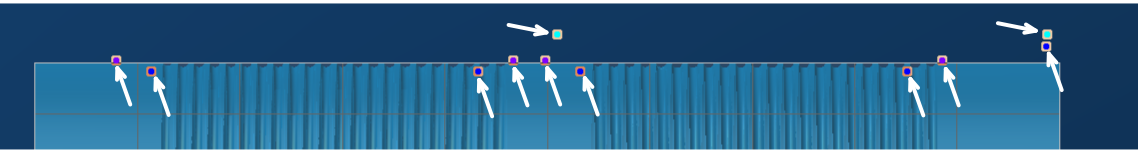

To do multiple surfaces for threading, place points in sets of 4 on the part.

Point 3 and 4 and point 7 and 8 are placed on the minor diameter of the thread.

Point 2 and 5 and point 6 and 9 are on major diameter.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

In this example, we want to machine a synchronized righthand and lefthand rope thread on the part.

After selecting the point that will run out of the first rightland thread(pt.5), select the entry point for the lefthand thread (pt.6) and select the rest of the points in Z+ direction. (pt 7,8,9)

If its required for the outer start thread helixes to be oriented equally on the part, start by setting the points 3. and 7. to have a distance relative to the pitch of the thread (whole revolutions).

If the pitch is 0.5", start with setting the distance between points 3. and 7. to whole revolutions. For example 30 x 0.5 = 15", meaning distance between point 3. and 7. to be 15"

If the placement of point 3. and 7. needs to be adjusted, translate the points the same amount in each direction.

Same with the length of the thread surfaces, distance between point 3. and 4. and point 7. and 8. must be identical length.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Confirm to use the points as a guided toolpath by clicking 'Yes' in the window.

Page accessed : 1680 times